Search

Looking for something in particular? Search for it here.

Looking for something in particular? Search for it here.

They purchased wet, swampy, low lying prairie, and installed tiles that drained the water to the nearest creek or stream. This drained soil was rich with nutrients and produced abundant crops.

In 1887 Bloomington’s Weekly Pantagraph reported that over 28,756,403 feet of tile had been installed in McLean County — the equivalent of over 5,400 miles.

“The amount of corn raised is larger than ever, owing to drainage...will probably continue to increase.”

— Bloomington Pantagraph

October 22, 1879

An expensive endeavor, districts were formed to fund, build, and regulate the drainage of excess water in fields.

In November of 1895, the Bloomington Pantagraph reported on a drainage district established in Logan County that saw amazing results.

“Fully 20,000 acres of land has been reclaimed by means of this drainage district. Of this amount about 10,000 acres were worthless. It was worth in the neighborhood of $10 per acre, but now easily brings $100. Not all of the 20,000 acres have been increased in value this much, but all of it has increased fully 100 percent.”

—

Bloomington Pantagraph

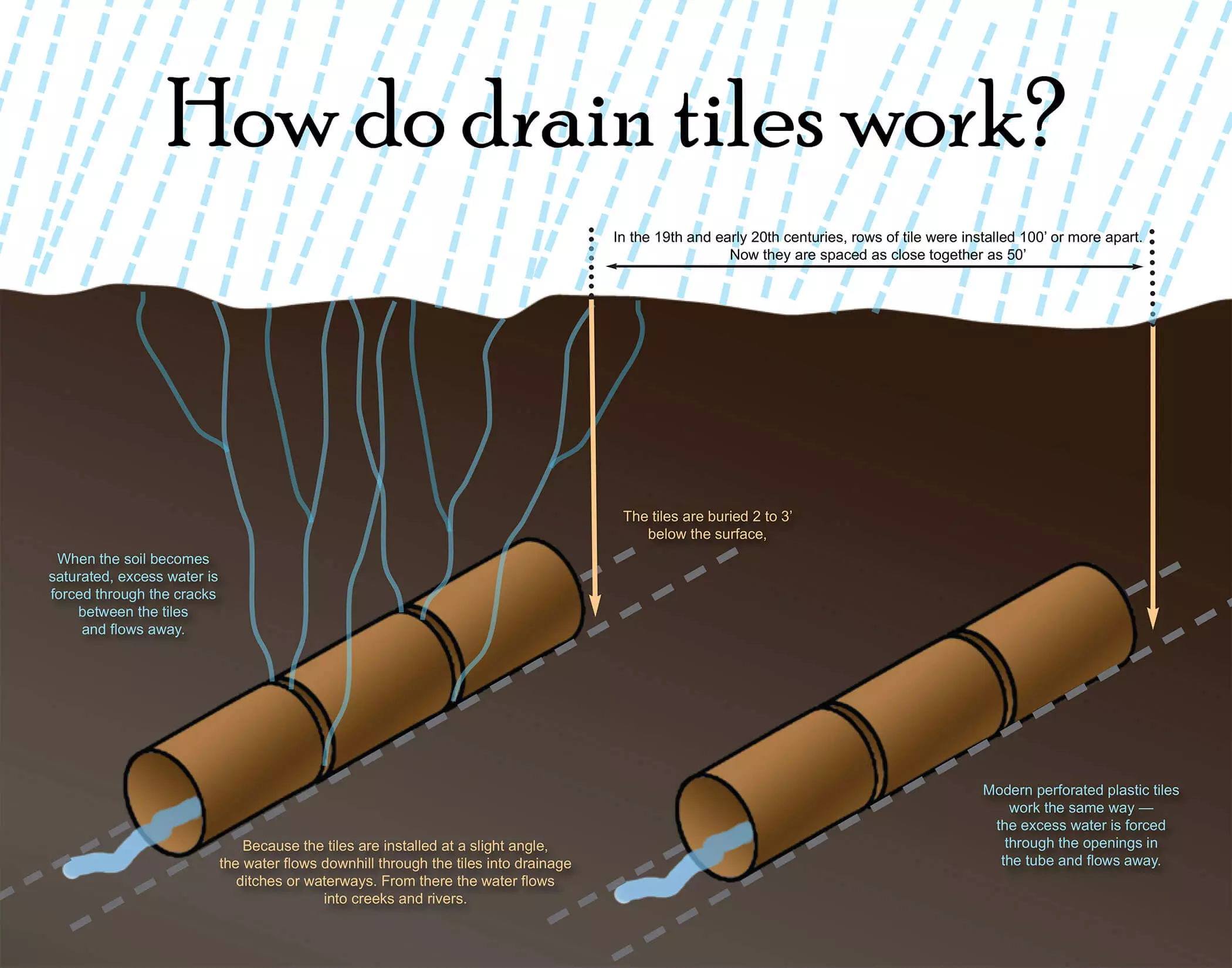

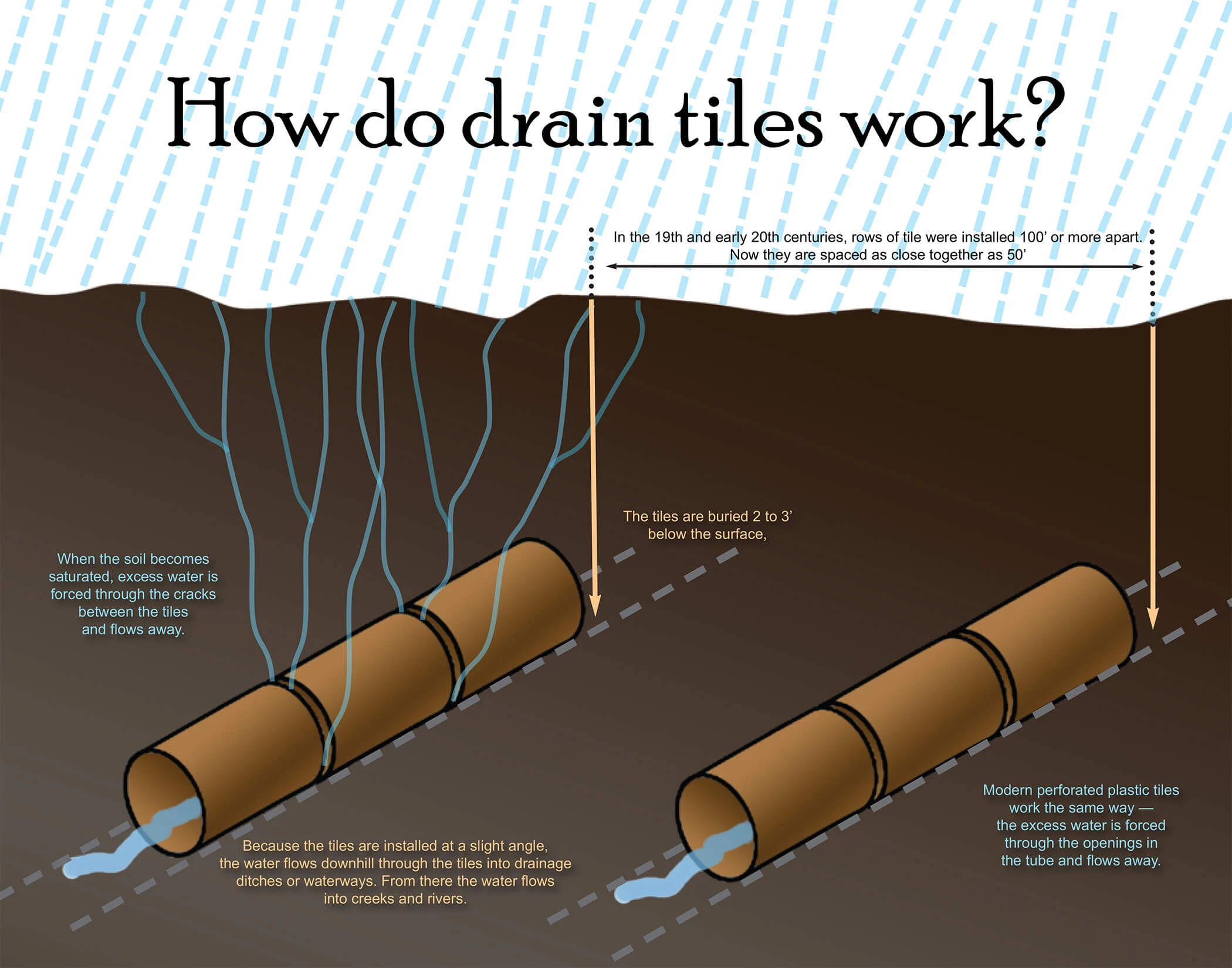

Drain tiles are buried 2' to 3' (0.6 m to 0.9 m) underground. When soil becomes saturated, excess water is forced through the cracks between the tiles and flows away, rather than flooding the fields. Because the tiles are installed at a slight angle, the water flows downhill into drainage ditches or waterways. From there, it flows into creeks or rivers. Modern perforated plastic tiles work the same way.

Corrugated Plastic Drainage Tile, circa 1980

View this object in Matterport

In the early 1960s McLean County farmers began to use perforated plastic tile for field drainage instead of clay or cement tiles.

Clay Drainage Tiles, circa 1900

View this object in Matterport

Tiles, like these, were installed underground to drain fields of excess water.

905.510

One hundred and fifty years after clay tiles were first installed in McLean County, farmers were still putting new tile into the ground. They were also replacing early tiles.

By the late 1970s the process was totally mechanized and the tile used was a perforated plastic tube.

In the spring of 1981 Fairbury farmer Maurice Abrahamson and his son Roger decided they could no longer cope with the delayed planting and lowered yields that resulted from wet springs and rainwater collecting in depressions on their 600 acre farm.

“Tile is as important as fertilizer.”

— Keith McClure